Perfect solution for warehouses without raised docks.

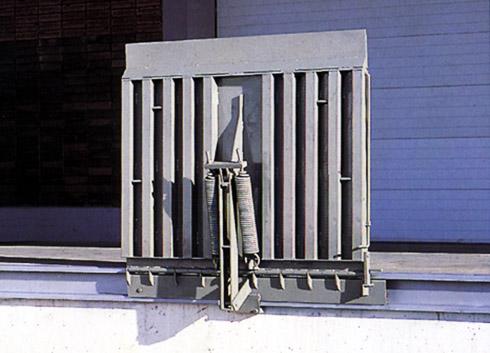

Elevating Docks

Elevating docks are the perfect solution for warehouses without raised docks, or when there is a great difference between the highest and lowest truck heights.

Elevating docks can be built in virtually any size and capacity required for the application. They provide the ability to service trucks at any height and can also offer fork trucks access to ground level.

Elevating docks are also available in a low-profile design to facilitate ground to truck loading/unloading without the need for a pit. This is particularly beneficial when dealing with a hand pallet truck and low volume product movement.

Specification:

- Various capacity ratings are available: 2.2t, 2.7t, 3.6t, 4.5t, 5.5t, 6.8t and 9.0t

- Come in various standard sizes for easy installation

- Can be mounted in a pit or anchored to a concrete pad

- Superior construction with full-length deck beam for maximum support and solid plate steel legs for maximum rigidity

- All pivot points are equipped with maintenance-free lubricated bushes and scissor leg roller bearings

- Fail-safe design prevents platform free-fall in case of hydraulic system failure

- Optional handrails and lip with lifting chain

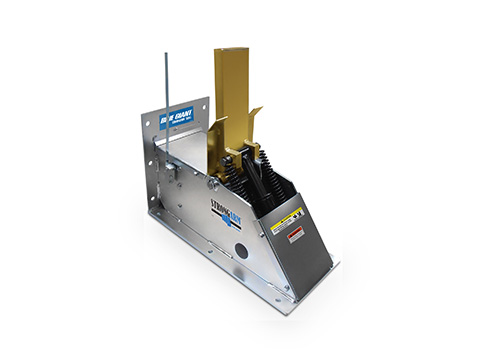

Mobile Elevating Docks

Where portability is required, a mobile elevating dock can also be considered. It features

the same design considerations as a fixed loading dock except that it can be moved and comes

with steel wheels.

Selecting the Correct Dock Lift:

- Determine the Lifting Capacity:

Lifting Capacity = Load Weight + Material Handling Equipment Weight + Operator WeightExample:

Load Weight: 4500lbs

Fork Truck Weight: 7300lbs

Operator Weight: 200lbs

Scissor Lift Capacity Required: 12,000lbs - Determine the Axle Capacity

The axle capacity is the amount of weight placed on a lift as the load and transport vehicle enters the lift.

This is the point at which the most stress is placed on the lift, as the weight is concentrated on one side of the lift. MHE-Blue Giant scissor lifts have a single axle

rating of 80% across the open ends and 50% across the sides.