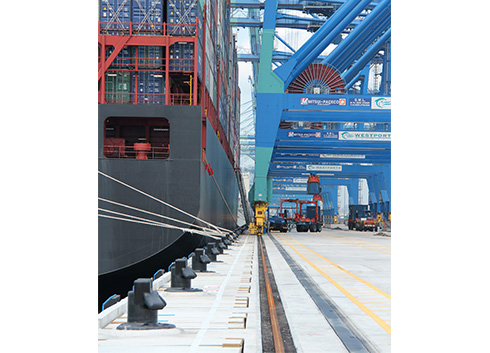

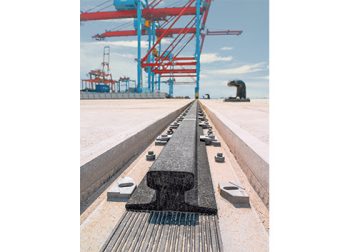

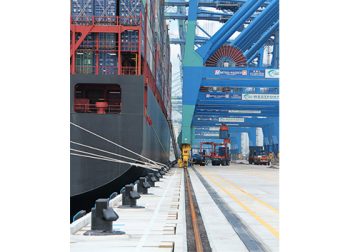

Choosing the right rail for your applications.

Rail

We offer a wide variety of rails to many different standards to suit your crane rail needs. Ranging from 15 to 150 kg per meter, there are over 100 sections available.

Features:

- Best price directly from the mill

- Rapid availability

- Alternative section suggested

- Drilling, bending and machining service are available

- Numerous grades available ranging from 690–1100 N/mm2

We have a wealth of knowledge on the subject of rails. The approach used for selecting rails differs around the world. Rails are not always rolled out as frequently as the industry demands. Thus we often suggest alternative or equivalent rails to customers.

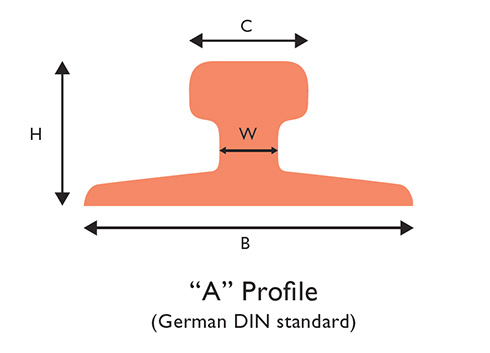

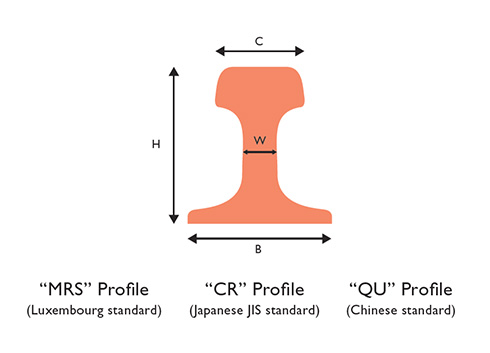

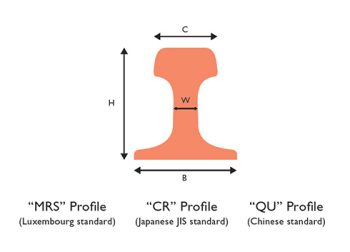

There are well over 100 rail selections to choose from. The main types are as follows:

- Crane rails with thick webs

- Railway-style rails with relatively thin webs

- Sections which are rectangular but which have flanges to form a foot

The crane supplier may suggest a rail but if they do not then, as a minimum, he should supply the head width of the rail. In designing or checking an installation, it is our practice to check that the rail will be suitable.

- Verifying of rail head suitability

- Validation of web strength to the application

- Accurate selection of rail grade for the expected lifecycle

Rail Drawings

A problem arises when a rail is chosen that is infrequently rolled out. Steel mills normally concentrate on rolling out commonly used products and crane rails are not always given priority. As a consequence, we often have to suggest an alternative. As there may be insufficient information to carry out a full check of the rail, we have developed systems that will give a good measure of confidence at an early stage in the project cycle.

Crane rail steels are formulated to give high wear resistance together with a suitable tensile strength. The strength ranges from 690 N/mm to 1100 N/mm but is typically in 880 N/mm.

With many types and selections of rails, some rails are able to use discontinuous sole plate mounting and some (especially A-Rail) have to use the continuous sole plate mounting only.